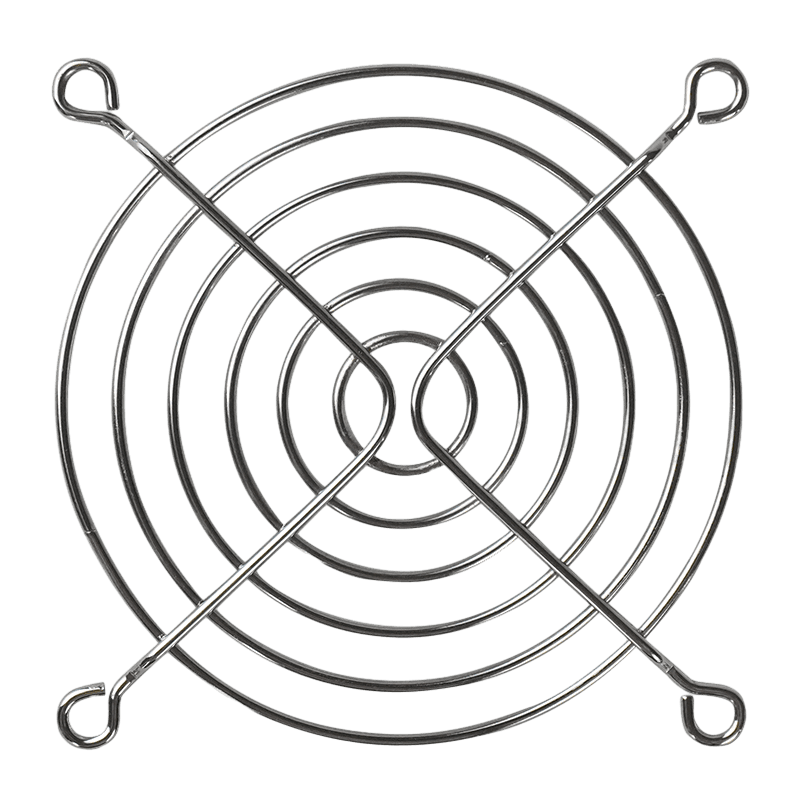

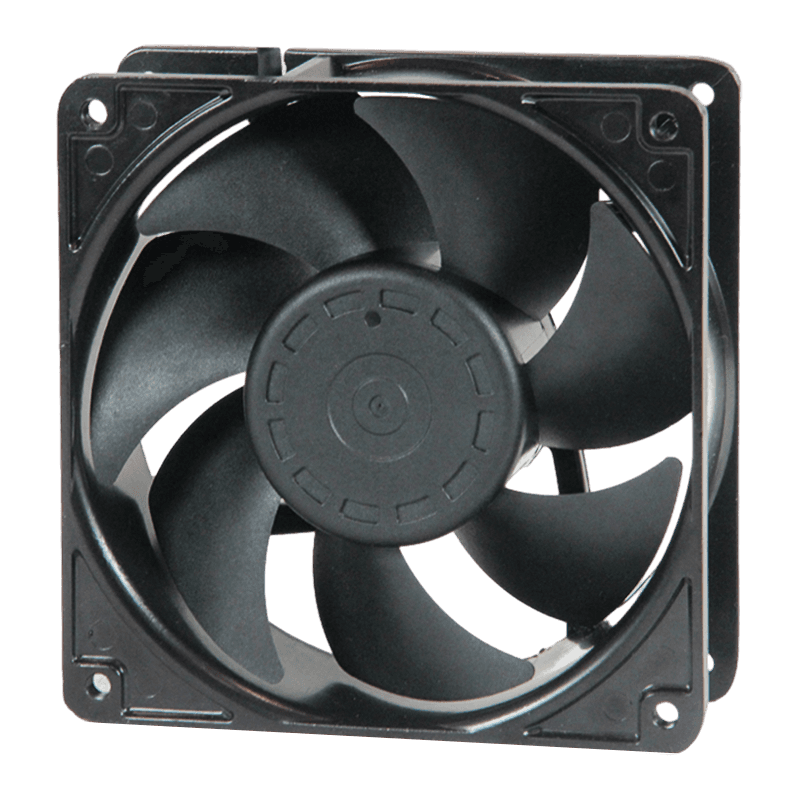

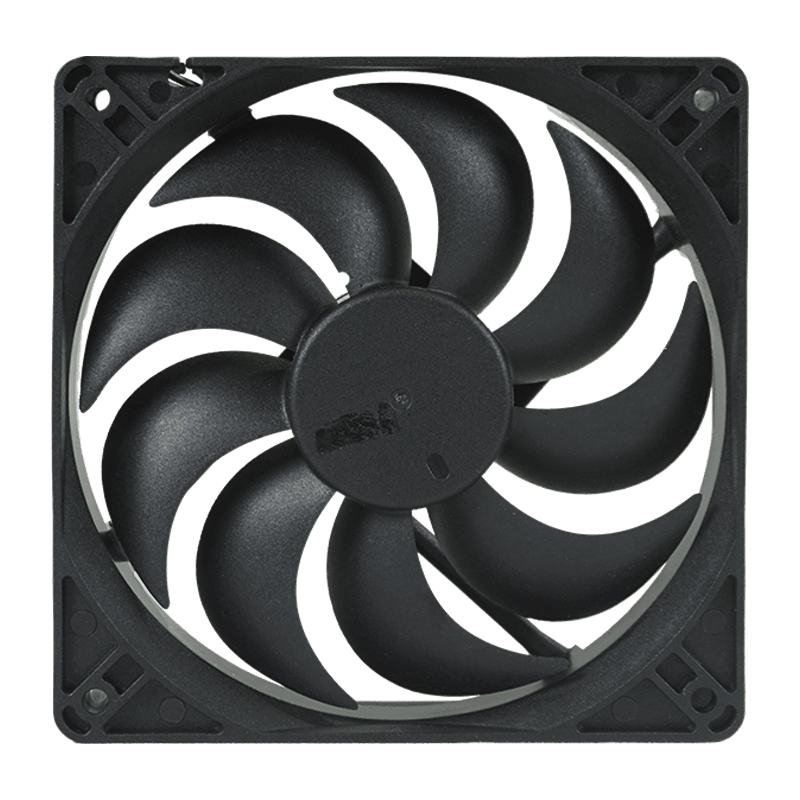

Exhaust fan type axial manufacturer and supplier in china

In the process of pursuing industrialization and modernization, human society is faced with a series of environmental challenges, among which noise pollution has increasingly become the focus of attention. As a widely used ventilation equipment in industrial and civil buildings, the noise generated by exhaust fan type axial can not be ignored. The purpose of this paper is to explore how the design and operation strategy of exhaust fan type axial can effectively reduce noise pollution and achieve a more environmentally friendly ventilation solution.

Understand noise sources

First of all, to reduce the noise of the exhaust fan type axial, it is necessary to deeply understand the root cause of the noise. The noise of exhaust fan type axial mainly comes from turbulence and mechanical vibration. Airflow turbulence is caused by sudden changes in speed and direction when air passes through the fan blades. The mechanical vibration is due to the unbalanced state of the motor, bearing and other parts at high speed.

Design optimization

In view of the above noise sources, designers can start from the following aspects to optimize the design of exhaust fan type axial to achieve the purpose of reducing noise:

1. Blade design: The use of new blade geometry and materials, such as increasing the number of blades, optimizing blade angle and thickness, can significantly reduce airflow turbulence and thus reduce noise. At the same time, the use of sound-absorbing materials to cover the blade surface can also effectively absorb part of the sound wave and reduce noise transmission.

2. Motor and drive system improvement: The selection of high-performance, low-vibration motors, as well as precision bearings and well-balanced drives, can significantly reduce mechanical vibration and thus reduce noise levels. In addition, the use of soft connections and shock absorbers can further isolate vibration and reduce the propagation of noise.

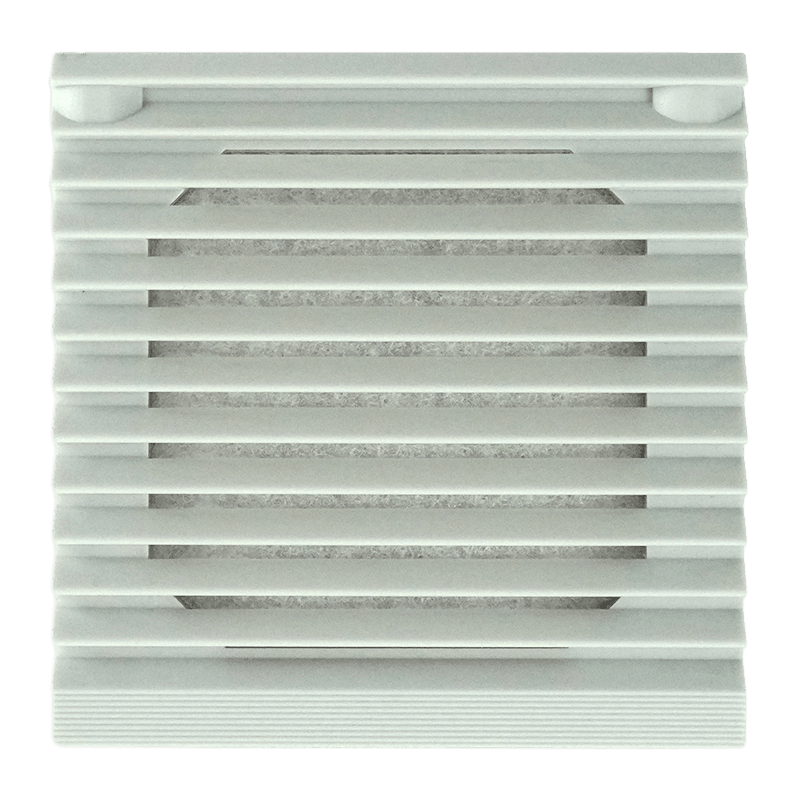

3. Optimization of the structure of the whole machine: The reasonable design of the shell and the guide cover can not only improve the efficiency of the air flow, but also play a sound insulation effect. By installing sound insulation materials around the exhaust fan or building sound insulation walls, the noise can be effectively blocked from spreading out.

Operation and maintenance

In addition to design level optimization, proper operation and regular maintenance of exhaust fan type axial are also key to reducing noise. This includes:

1. Regular inspection and maintenance: Check bearing lubrication regularly, replace worn parts in time, and maintain the good condition of the motor and transmission system, which can avoid additional noise caused by failure.

2. Reasonable choice of operation mode: According to the actual ventilation needs, adjust the running speed and time of the exhaust fan type axial to avoid unnecessary high-speed operation, thereby reducing noise emissions.

3. Noise monitoring and feedback: Install noise monitoring equipment to monitor the noise level during the operation of the exhaust fan in real time, and take immediate measures to adjust or maintain once an anomaly is found.

Conclusion

While providing efficient ventilation, exhaust fan type axial should not become the source of environmental pollution. Through continuous technological innovation and scientific management, we are fully capable of controlling noise pollution and achieving a harmonious coexistence between industrial development and environmental protection. In the future, with the continuous emergence of new materials and new technologies, exhaust fan type axial are expected to become a more environmentally friendly and efficient ventilation solution, and contribute to the construction of a beautiful earth.

Through the implementation of the above design optimization and operation and maintenance strategy, the exhaust fan type axial can not only ensure the ventilation efficiency, but also significantly reduce noise pollution, but also extend the life of the equipment, save energy consumption, and finally achieve a win-win situation of economic benefits and environmental protection.

English

English 中文简体

中文简体 عربى

عربى