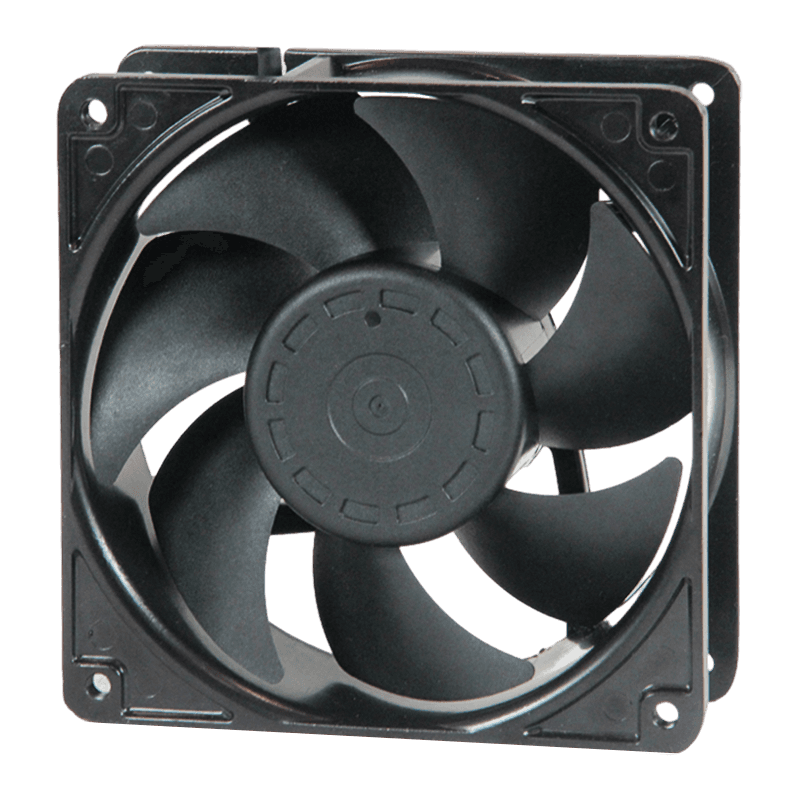

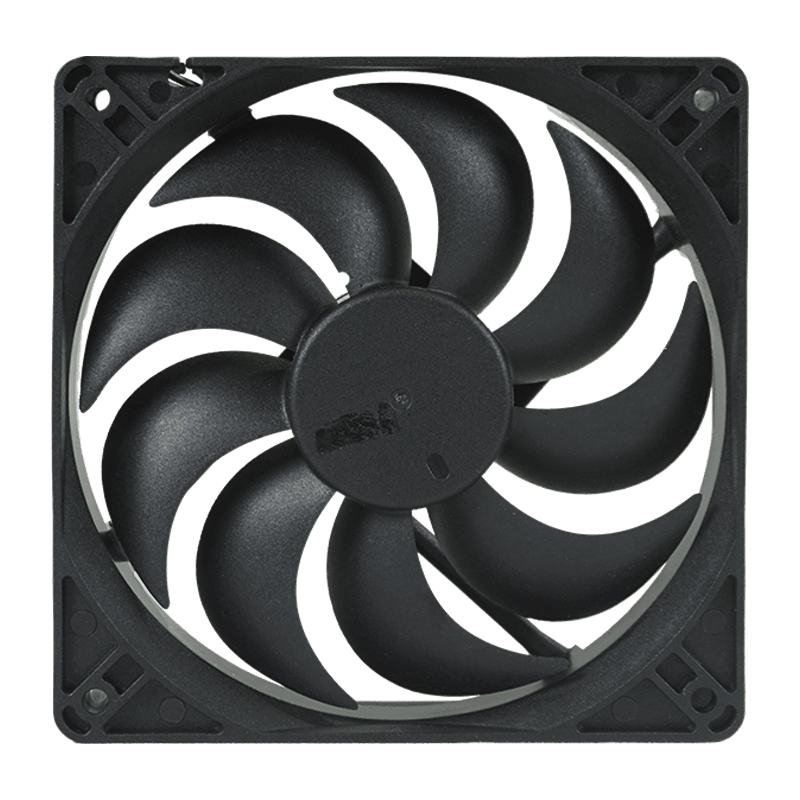

High quality wholesale axial air mover fan for sale

In many fields such as industrial production, building ventilation, data center cooling, and environmental protection equipment, axial air mover fans are key equipment, and their selection directly affects the operating efficiency, energy consumption, and maintenance costs of the system. Therefore, how to accurately select the right axial air mover fan according to the needs of different industries has become a topic worthy of in-depth discussion.

1.Clear industry requirements and application scenarios

It is necessary to clarify the specific application scenarios and requirements before selecting the axial air mover fan. Different industries have different requirements for the air volume, wind pressure, noise, energy efficiency ratio and other parameters of the fan. For example, in the data center, low noise, high efficiency and continuous stable operation of the fan is needed to ensure good heat dissipation of the server; In the industrial production line, more attention may be paid to the durability and corrosion resistance of the fan to adapt to the harsh production environment.

2.Understand the basic types of axial air mover fans

axial air mover fans can be divided into different types according to impeller design and installation, such as axial-flow fans, centrifugal fans and so on. Axial-flow fans are known for their rectilinear airflow path and high air volume output, especially for applications where large amounts of air flow are required. Understanding and comparing the characteristics of different types of axial air mover fans helps to more accurately match industry needs.

3. Focus on key performance indicators

Air volume and pressure: Select an appropriate axial air mover fan model based on the required air volume (volume of air passing through the fan per unit time) and air pressure (pressure difference generated by the fan) for the application scenario. Insufficient air volume will result in poor heat dissipation, and insufficient wind pressure may not be able to overcome system resistance.

Efficiency and energy consumption: Efficient fans consume less electricity for the same amount of air, thus reducing operating costs. Therefore, the selection should pay attention to the energy efficiency ratio and power factor of the fan and other parameters.

Noise level: For places that require a low noise environment, such as hospitals, libraries, etc., it is crucial to choose an axial air mover fan with a low noise design.

Material and durability: According to the corrosion, temperature, humidity and other factors of the application environment, choose the appropriate material and protective measures to ensure that the fan can run stably in harsh environments.

4.Consider the ease of installation and maintenance

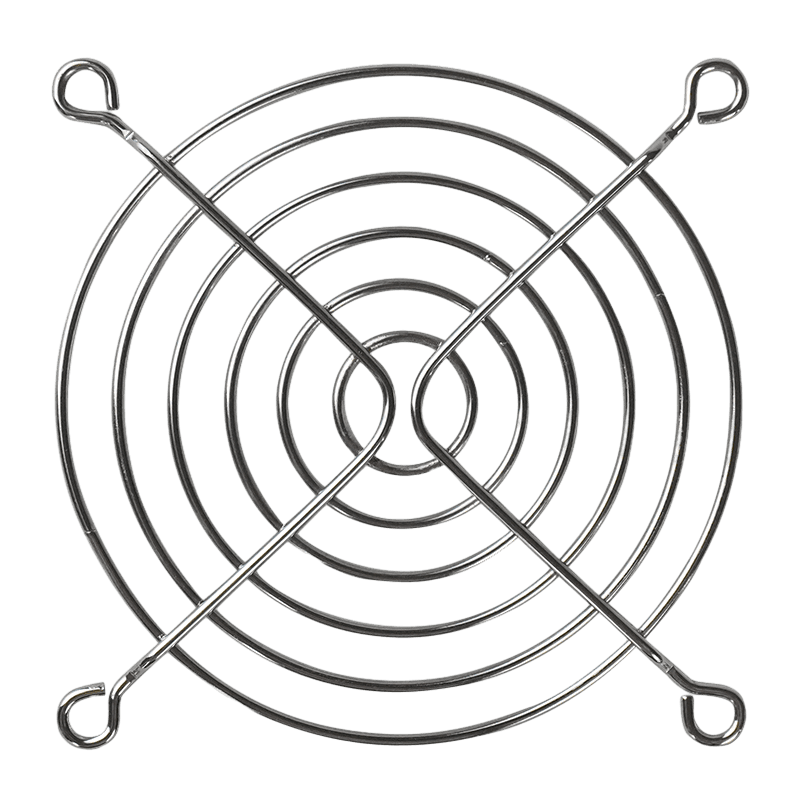

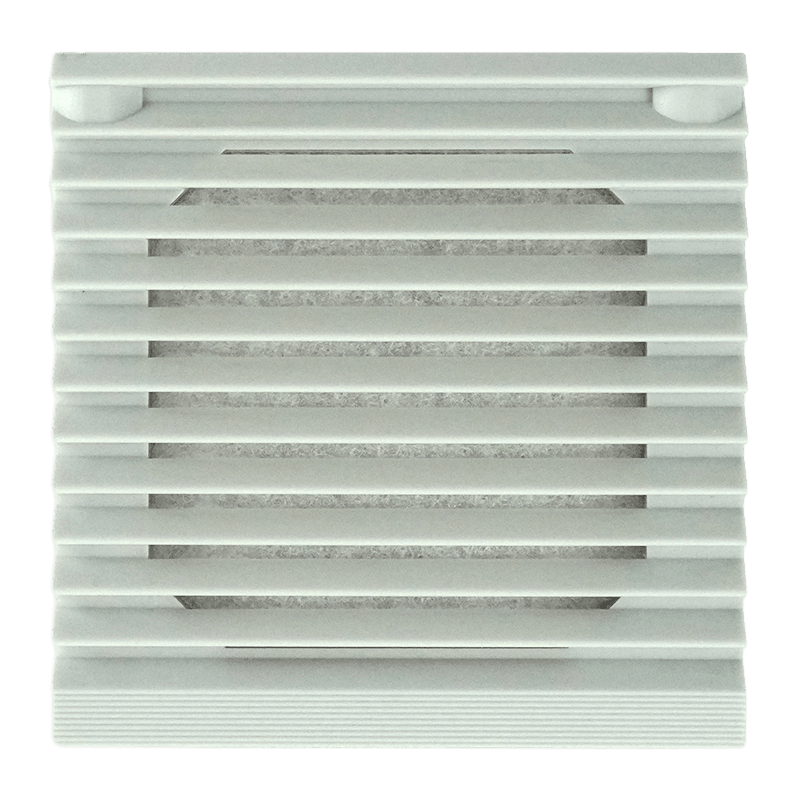

The installation space, connection mode, and maintenance difficulty of the axial air mover fan are also factors that need to be considered when choosing. Some industries may have limited space and need to choose models with compact structure and easy installation; At the same time, the design of easy disassembly and maintenance can reduce subsequent operation and maintenance costs.

5. Refer to successful cases and manufacturers' strength

Understanding the successful cases of similar application scenarios in the industry can provide us with valuable references. At the same time, choosing a strong manufacturer can not only ensure the quality and performance of the product, but also obtain more professional technical support and after-sales service.

6. Comprehensive evaluation and selection

After clarifying the industry needs, understanding the type and performance indicators of the fan, and considering the ease of installation and maintenance, it is necessary to conduct a comprehensive evaluation and selection. By comparing different brands and different models of axial air mover fans, combined with cost budget and long-term benefit analysis, choose the suitable axial air mover fans for the current industry needs.

In short, choosing the right axial air mover fan is a complex process involving many factors. Only by fully understanding the needs of the industry, mastering the knowledge of fans, and comprehensively considering various factors can we make a scientific and reasonable choice, which provides a strong guarantee for the stable operation of the system and energy saving and consumption reduction.

English

English 中文简体

中文简体 عربى

عربى