Cheap Axial Air Blower Wholesaler

Axial air blowers are essential devices used in various applications, from industrial processes to HVAC systems. Their efficiency and performance are significantly influenced by several design factors, including blade shape, number of blades, and materials used in construction. Understanding these elements is crucial for optimizing the performance of axial air blowers and ensuring they meet the specific needs of their applications.

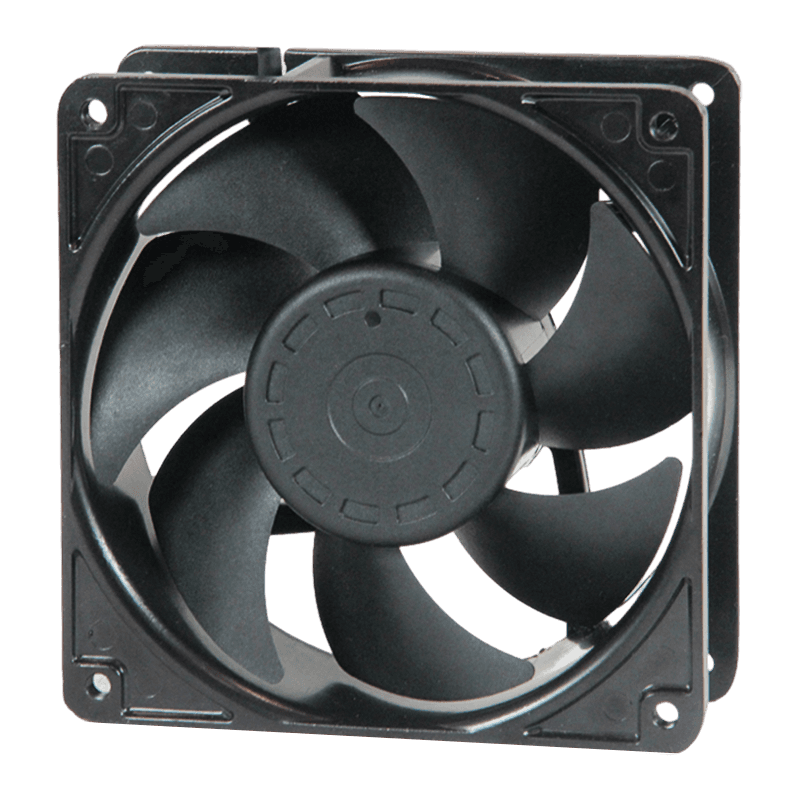

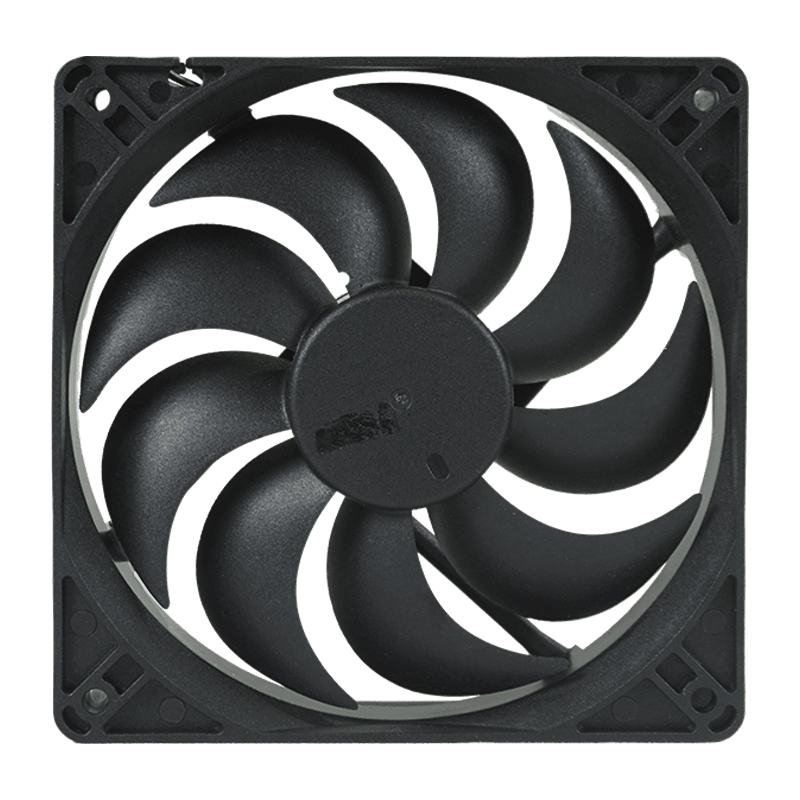

The shape of the blades in an axial air blower plays a pivotal role in determining airflow characteristics and overall efficiency. Blades can be designed in various configurations, such as straight, curved, or twisted. Each shape affects how air flows through the blower. For instance, blades with a forward curve can enhance airflow at lower speeds, making them suitable for applications requiring high volume but low pressure. Conversely, backward-curved blades are more efficient at higher pressures and are often used in applications where consistent airflow is critical. The design of the blade tips also matters; rounded tips can reduce turbulence and noise, while sharper tips may increase efficiency but can also cause higher noise levels.

The number of blades in an axial air blower is another critical factor influencing performance. Generally, increasing the number of blades can enhance airflow and pressure capabilities. However, there is a trade-off; more blades can also cause increased drag and noise. Therefore, the ideal number of blades depends on the specific application requirements. For example, blowers designed for high-pressure applications may benefit from fewer, more robust blades, while those intended for high-volume airflow may utilize a greater number of thinner blades to maximize efficiency.

Material selection is equally important in the design of axial air blowers. The materials used for blades can significantly impact their durability, weight, and performance. Common materials include metals, plastics, and composites. Metal blades, such as those made from aluminum or steel, offer strength and durability, making them suitable for heavy-duty applications. However, they can be heavier, which may affect the blower's overall efficiency. On the other hand, plastic blades are lighter and can be molded into complex shapes, allowing for innovative designs that enhance performance. Composites combine the benefits of both materials, offering strength while reducing weight, which can cause improved efficiency and reduced energy consumption.

The interplay between blade shape, number, and material ultimately determines the performance of an axial air blower. For instance, a blower with backward-curved blades made from lightweight composite materials may achieve higher efficiency and lower noise levels compared to a similar blower with metal blades. Additionally, the design of the blower housing and the arrangement of the blades can further influence performance. A well-designed housing can minimize turbulence and optimize airflow, enhancing the overall effectiveness of the blower.

In practical applications, the choice of axial air blower must align with the specific requirements of the system it serves. For example, in a cooling system for industrial machinery, a blower with a higher number of blades and a backward curve may be preferred to maintain consistent airflow under varying load conditions. Conversely, in a residential ventilation system, a blower with fewer blades and a forward curve may be more suitable for quiet operation and efficient airflow.

Regular maintenance and monitoring of axial air blowers are also essential to ensure they operate at peak performance. Over time, wear and tear can affect blade shape and material integrity, causing decreased efficiency and increased noise. Implementing a routine maintenance schedule can help identify issues early and prolong the lifespan of the blower.

In conclusion, the performance of axial air blowers is significantly influenced by blade shape, number, and material. Each of these factors plays a crucial role in determining airflow characteristics, efficiency, and noise levels. By carefully considering these design elements, manufacturers can optimize axial air blowers for specific applications, ensuring they meet the demands of various industries. As technology advances, the development of innovative blade designs and materials will continue to enhance the performance of axial air blowers, making them even more effective in their roles.

English

English 中文简体

中文简体 عربى

عربى