Wholesale High Temperature Axial Fan Producer

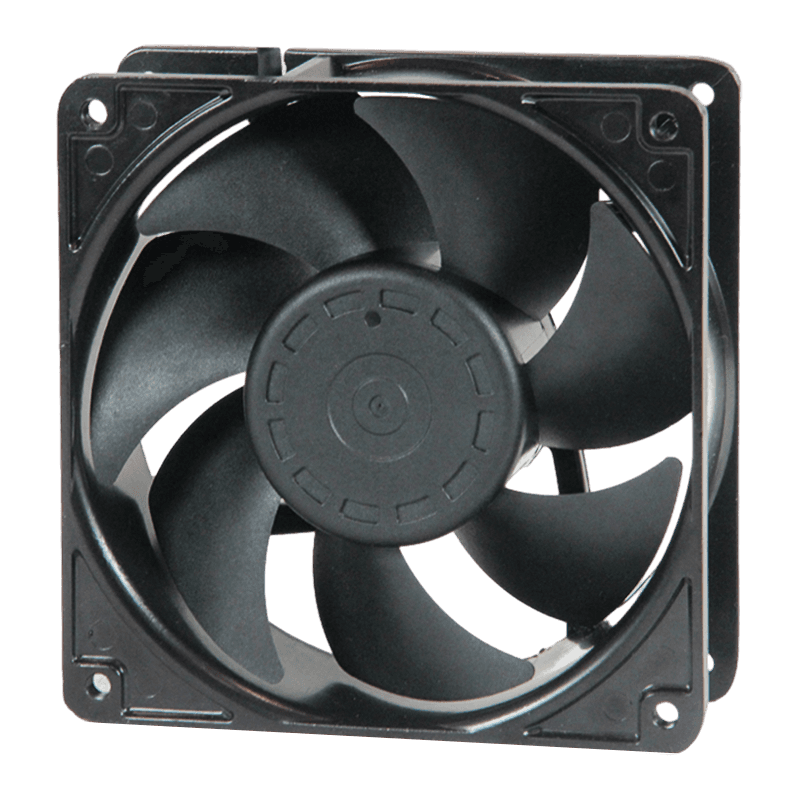

High temperature axial fans are engineered to operate in environments where conventional fans would fail. These fans are essential in various industrial applications, including furnaces, ovens, and heat treatment equipment, where temperatures can soar well beyond the capabilities of standard fans. The ability of a high temperature axial fan to withstand such conditions is primarily due to its specialized design and the materials used in its construction.

One of the significant advantages of high temperature axial fans is their temperature tolerance. These fans can typically operate at temperatures exceeding 1,000°F (538°C), making them suitable for demanding applications. The design of a high temperature axial fan includes features that allow it to maintain performance and structural integrity under these harsh conditions. For instance, the fan blades are often constructed from high-strength materials that resist deformation and wear, ensuring longevity and reliability.

The materials used in high temperature axial fans are crucial to their performance. Commonly, manufacturers utilize stainless steel, aluminum alloys, and specialized plastics that can endure high temperatures without losing their mechanical properties. Stainless steel is particularly favored for its corrosion resistance and strength, making it ideal for environments where exposure to heat and chemicals is common. Aluminum alloys offer a lightweight alternative that still provides adequate strength and thermal resistance, while advanced plastics can be engineered to withstand high temperatures and provide additional benefits such as reduced weight and improved energy efficiency.

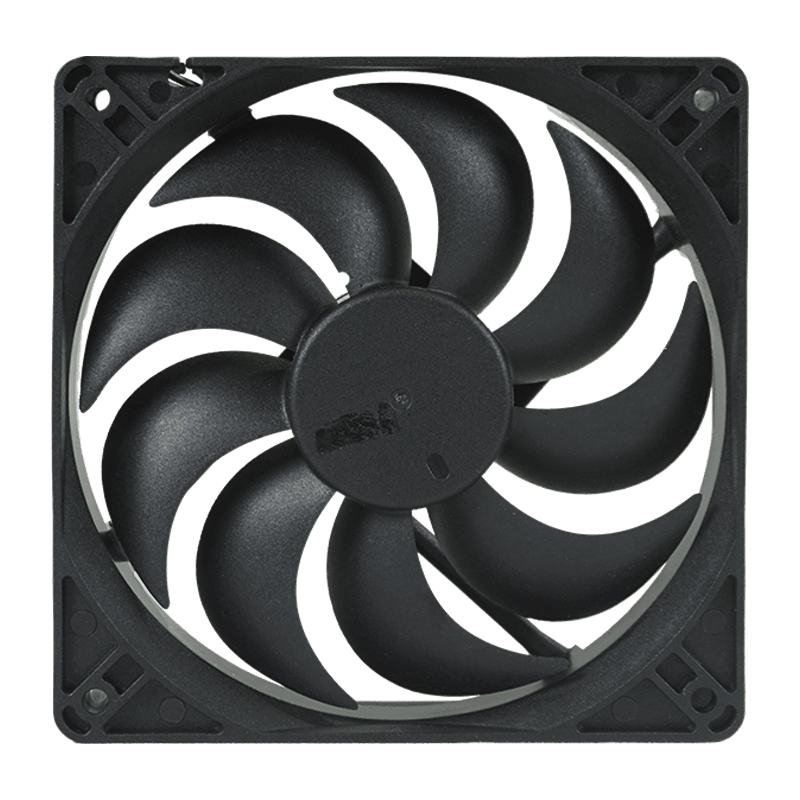

In addition to the materials, the design of the blades in a high temperature axial fan is tailored to optimize airflow while minimizing turbulence. The shape and angle of the blades are critical in determining how effectively the fan can move air at high temperatures. Blades are often designed with a specific curvature that enhances airflow efficiency, allowing the fan to deliver consistent performance even under outstanding conditions. This design consideration is vital in applications such as industrial furnaces, where uniform airflow is necessary to achieve consistent heating and processing results.

The construction of the motor and other components in a high temperature axial fan also plays a significant role in its overall performance. Motors used in these fans are typically designed to operate at elevated temperatures, featuring enhanced insulation and cooling mechanisms to prevent overheating. This ensures that the fan can run continuously without risk of failure, which is essential in industrial settings where downtime can cause significant losses.

Another important aspect of high temperature axial fans is their ability to handle varying airflow requirements. Many applications require fans that can adjust their performance based on the specific needs of the process. Some high temperature axial fans are equipped with variable speed drives, allowing operators to control the fan speed and airflow dynamically. This flexibility not only improves energy efficiency but also enhances the effectiveness of the heating or cooling process.

Maintenance is also a critical consideration for high temperature axial fans. Regular inspections and servicing are necessary to ensure that all components remain in good condition, especially given the harsh operating conditions. Proper maintenance can extend the lifespan of the fan and prevent unexpected failures, which is particularly important in high-stakes industrial environments.

In conclusion, high temperature axial fans are indispensable in industries that require reliable airflow solutions in outstanding conditions. Their ability to withstand high temperatures is a result of advanced engineering and the use of specialized materials. By optimizing blade design, utilizing durable materials, and incorporating robust motor systems, these fans provide efficient and effective performance in demanding applications. As industries continue to evolve and face new challenges, the development of high temperature axial fans will play a crucial role in ensuring operational efficiency and safety in high-temperature environments. The ongoing innovation in materials and design will further enhance the capabilities of high temperature axial fans, making them even more vital in the future.

English

English 中文简体

中文简体 عربى

عربى