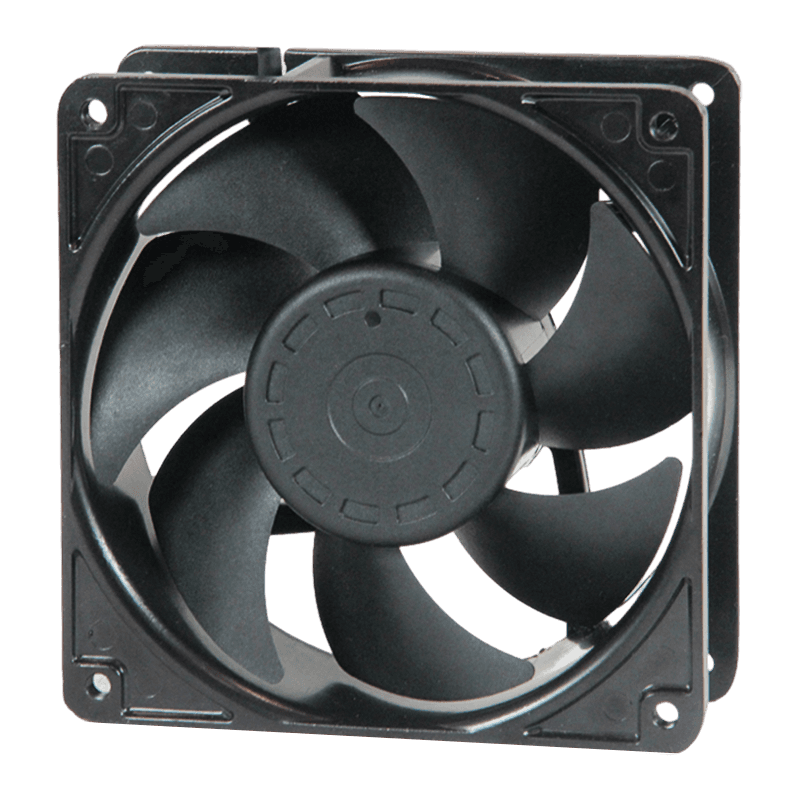

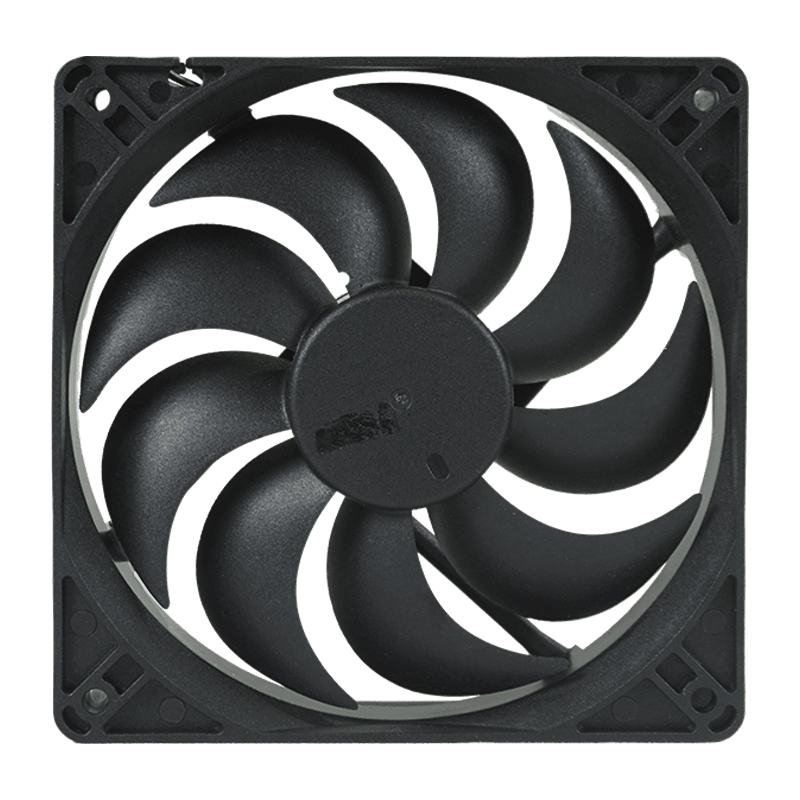

Custom 220v axial fan manufacturing factory

In the field of ventilation and heat dissipation, the 220V axial fan plays a crucial role. Its performance parameters directly determine its ventilation and heat dissipation effect and applicability in different scenarios.

I. Air Volume and Wind Speed

The air volume and wind speed output capabilities of the 220V axial fan are one of the key indicators to measure its performance. Under different working conditions, such as changes in environmental temperature and air density, it will have an impact on its air volume and wind speed. The larger the air volume, the more air volume can be pushed per unit time, thereby more effectively carrying out air exchange and improving the ventilation effect. The wind speed determines the speed of air flow. For heat dissipation, the appropriate wind speed can quickly take away the heat. For example, in the heat dissipation of some electronic devices, sufficient wind speed is required to ensure that the heating elements such as chips are cooled in time. The air volume and wind speed of the 220V axial fan have a decisive effect on the ventilation and heat dissipation effect. When choosing a fan, it is necessary to determine the appropriate air volume and wind speed index according to the actual demand. If the space is large and the heat dissipation demand is high, it is necessary to choose a 220V axial fan with a large air volume and wind speed; for some scenarios that require continuous and stable ventilation but have low requirements for wind speed, the wind speed requirements can be appropriately reduced while ensuring a certain air volume.

II. Wind Pressure

Wind pressure is another important concept in axial fans. It refers to the pressure generated by the fan during operation and is divided into static pressure and dynamic pressure. The range of static pressure and dynamic pressure that the 220V axial fan can generate determines its performance in different ventilation systems. Static pressure is mainly used to overcome the resistance of ventilation ducts and the like, while dynamic pressure is related to the kinetic energy of air. Wind pressure is closely related to the ventilation distance. The longer the ventilation distance, the greater the wind pressure required to overcome the frictional resistance and other factors when air flows in the pipeline. At the same time, resistance will also affect the distribution of wind pressure. When there are obstacles or pipe bends in the ventilation system, the wind pressure will change accordingly. Understanding the wind pressure characteristics of the 220V axial fan is helpful for the reasonable design of ventilation systems to ensure that the fan can effectively transport air in practical applications.

III. Rotational Speed and Power

The rotational speed of the fan has a significant impact on the performance of the 220V axial fan. Generally speaking, the higher the rotational speed, the corresponding increase in air volume and wind pressure. However, the increase in rotational speed will also bring some problems, such as increased energy consumption and increased noise. Different powers of 220V axial fans are suitable for different scenarios. Fans with lower power are usually suitable for occasions with low ventilation requirements and sensitive to energy consumption, such as small household ventilation equipment; while fans with higher power can be used in environments such as industrial production that require strong ventilation and heat dissipation capabilities. When choosing, users need to make a trade-off between energy saving and performance. If you pursue high-performance ventilation and heat dissipation effects, you can choose a 220V axial fan with higher power and rotational speed, but pay attention to energy consumption costs; if there are strict requirements for energy consumption, you can choose a fan with moderate power and reasonable rotational speed on the premise of meeting ventilation needs.

IV. Noise Level

The reasons for the noise generated when the 220V axial fan is running mainly include the friction between the impeller rotation and the air, and the operation of the motor. The generation of noise will not only affect the comfort of the use environment, but may also be limited in some places with strict noise requirements. The indicators for measuring noise usually include decibel values. In order to reduce noise, the 220V axial fan adopts a variety of technical measures, such as optimizing the impeller design, using sound insulation materials, and improving the motor structure. In practical applications, different models of 220V axial fans have different noise level performances. When choosing, users need to comprehensively consider according to the noise requirements of the use environment. For example, in a quiet environment such as an office, it is necessary to choose a 220V axial fan with a lower noise level to avoid interference with personnel work.

In summary, the performance parameters of the 220V axial fan, such as air volume and wind speed, wind pressure, rotational speed and power, and noise level, are interrelated and affect its application effects in different scenarios. When users choose and use the 220V axial fan, they need to fully understand these performance parameters and make reasonable choices and configurations according to actual needs to ensure that it can exert better ventilation and heat dissipation performance, while meeting requirements in terms of energy saving and noise, providing a good ventilation environment guarantee for various application scenarios. Whether in the industrial field or in daily life, the 220V axial fan plays an important role with its unique performance characteristics, bringing convenience and comfort to our production and life.

English

English 中文简体

中文简体 عربى

عربى