Cheap and high quality 150mm axial fan supply

In today's rapidly advancing technological era, heat dissipation has emerged as a crucial challenge for the stable operation of numerous electronic devices. Among the myriad of cooling solutions, 150mm axial fans stand out for their efficiency and cost-effectiveness, finding widespread applications in computer cases, industrial equipment cooling, and beyond. This article delves into the cooling performance of 150mm axial fans across various application scenarios, examining the delicate balance between airflow, air pressure, and noise—with the keyword "150mm axial fan" appearing at least ten times throughout the text.

I. Cooling Performance in Computer Cases

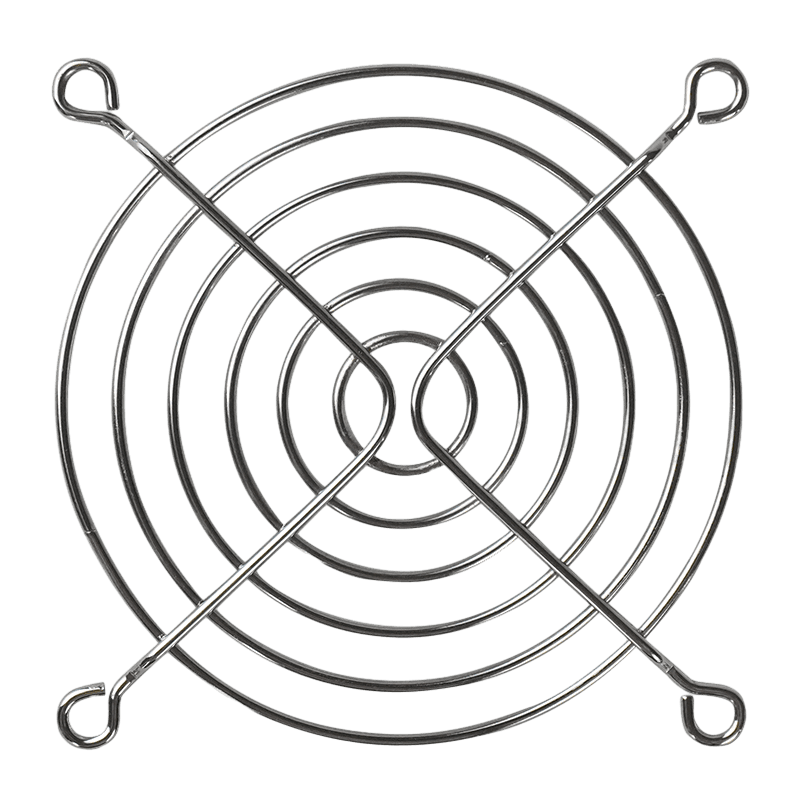

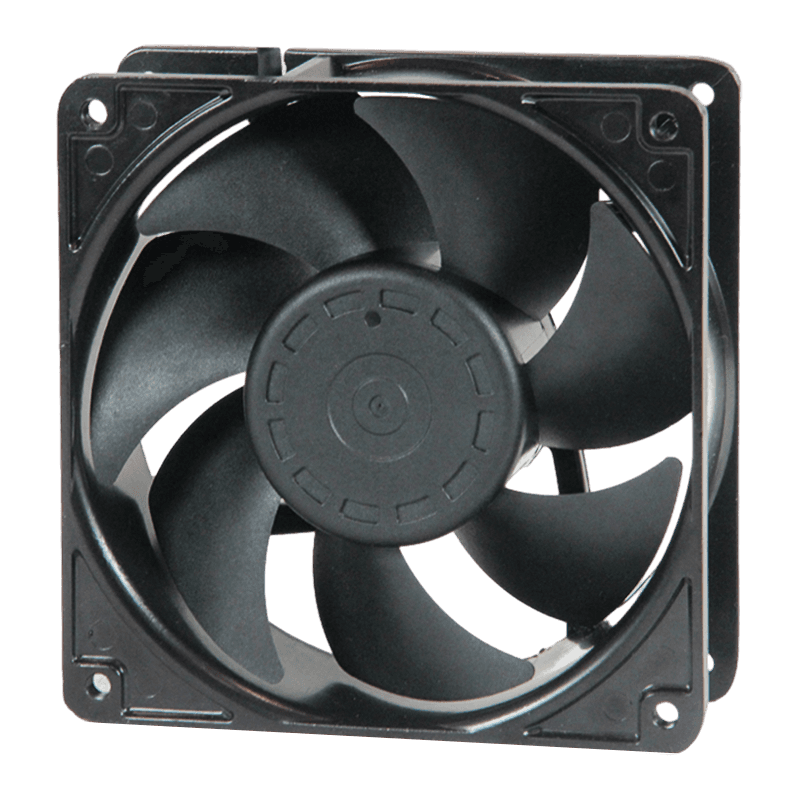

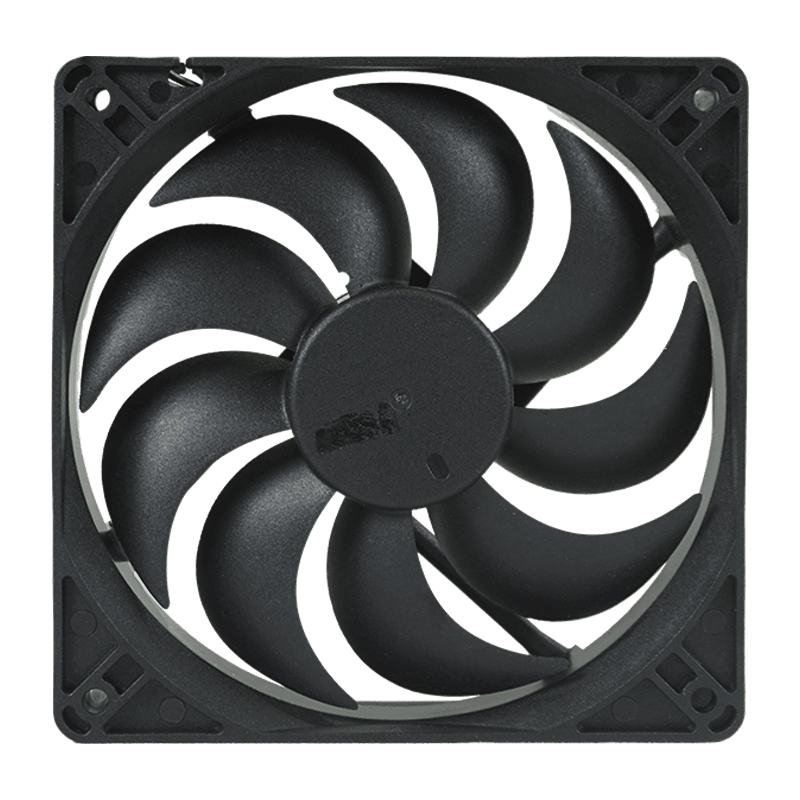

Within computer cases, core components such as processors and graphics cards generate significant heat during operation. Failure to dissipate this heat promptly can severely impact hardware performance or even cause system failure. The 150mm axial fan, with its large blade diameter and optimized airflow design, has become a preferred choice for high-end computer case cooling systems. These fans not only provide ample airflow to quickly dissipate heat within the case but also adjust their speed to adapt to varying cooling demands. In silent mode, they maintain a low noise level while ensuring adequate cooling; in high-performance mode, they operate at full speed to maximize airflow and ensure hardware safety.

II. Demonstrating Efficiency in Industrial Equipment Cooling

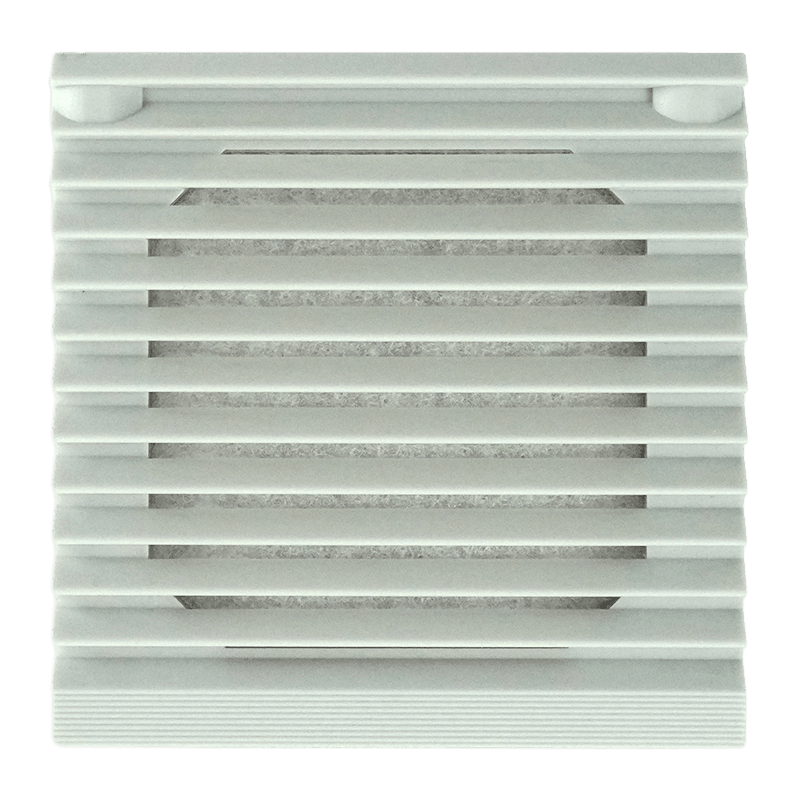

In industrial settings, devices like server rooms and automated production lines also face significant cooling challenges. These environments often have limited space and stringent temperature control requirements. The 150mm axial fan, with its efficient cooling and stable operation, plays a vital role in industrial equipment cooling systems. Its high airflow design rapidly reduces temperatures around the equipment, while its optimized air pressure distribution effectively penetrates dense heat sources within the devices for comprehensive cooling. Furthermore, industrial-grade fans employ long-life, high-temperature-resistant bearings and motors to ensure continuous stable operation under harsh conditions.

III. The Art of Balancing Airflow, Air Pressure, and Noise

When evaluating the cooling performance of 150mm axial fans, airflow, air pressure, and noise are three indispensable factors. Airflow determines the total amount of heat the fan can dissipate, while air pressure influences its ability to penetrate dense heat sources. However, as airflow and air pressure increase, so does noise. Therefore, achieving the balance between cooling effectiveness and noise levels is a critical aspect of fan design and application.

Manufacturers continuously optimize fan blade shapes, angles, and quantities, adopting advanced motor control technologies and vibration-damping materials to reduce noise and improve energy efficiency. Users can also tailor the cooling effect and noise level by adjusting fan speeds and installation positions based on their specific needs. For instance, in scenarios requiring high cooling efficiency, high-speed, high-airflow fans may be selected; in noise-sensitive environments, low-speed, low-noise fans can be utilized, with the addition of more fans or optimized air duct designs to enhance overall cooling performance.

IV. Conclusion

In conclusion, the 150mm axial fan, with its remarkable cooling performance, versatility across various applications, and the intricate balance between airflow, air pressure, and noise, has emerged as a pivotal force in modern electronic device cooling. Whether in computer cases or industrial equipment cooling systems, its presence is ubiquitous. As technology advances and application demands diversify, we can anticipate that future 150mm axial fans will become even more intelligent, efficient, and environmentally friendly, providing a more robust safeguard for the stable operation of devices across industries.

English

English 中文简体

中文简体 عربى

عربى