ODM 12v axial fan manufacturer and exporter

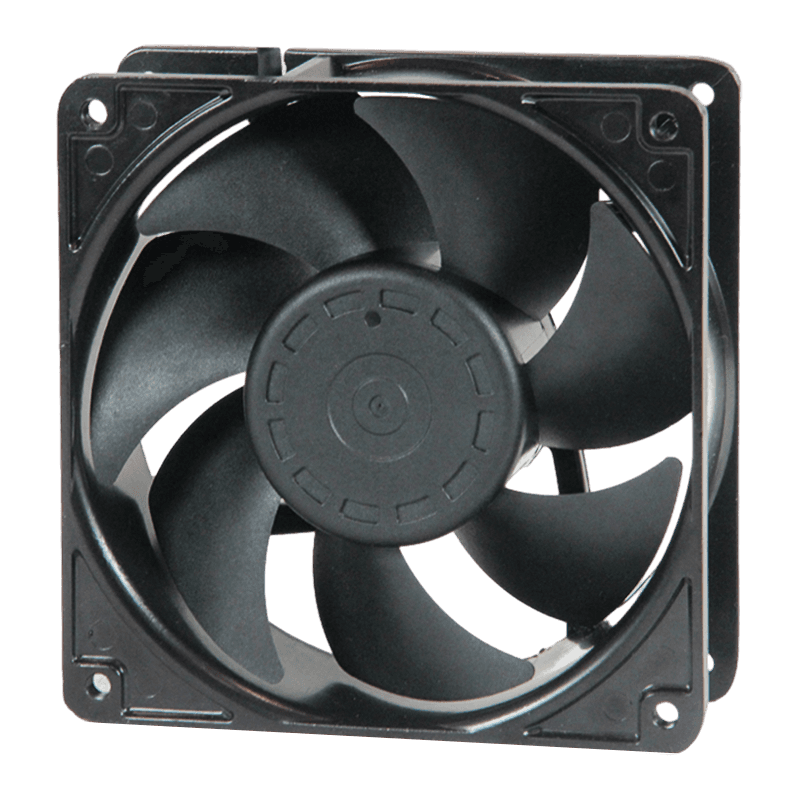

Among the many types of fans, the 12v axial fan is popular because of its compact structure, efficient performance and suitable for cooling a variety of electronic devices. The design and construction of a 12V axial fan directly affects its performance, including blade shape, motor type and material selection, which are carefully designed to optimize its efficiency and durability.

Axial flow fans work by rotating the blades to push the air along the axial flow. 12V axial fans are typically driven by DC motors, which makes them particularly suitable for devices that use battery or DC power. The selection of this motor type not only ensures the efficient operation of 12v axial fans in low-pressure environments, but also reduces energy consumption and improves the overall energy efficiency.

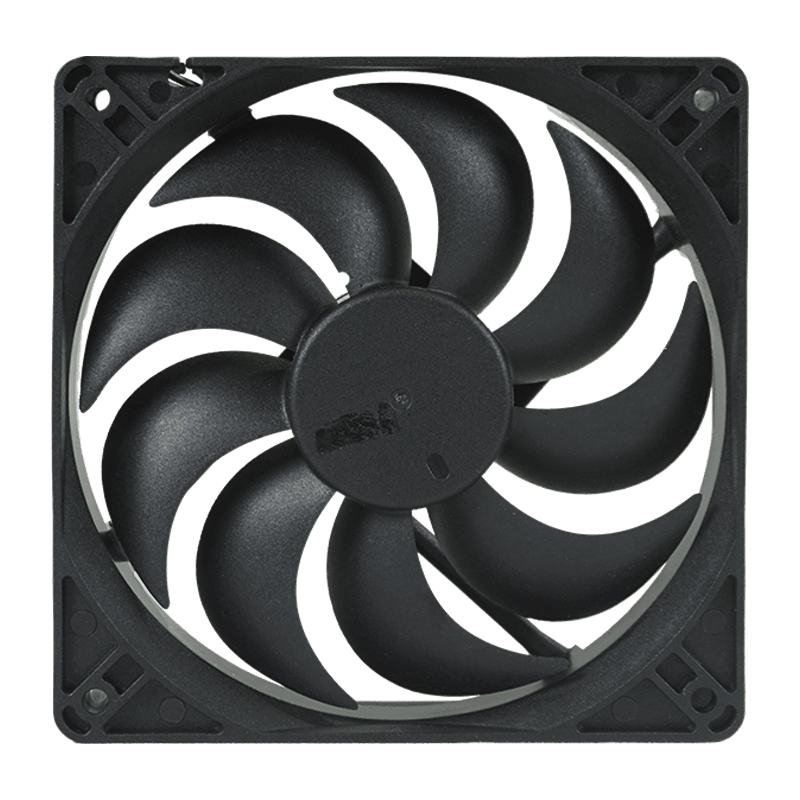

In terms of blade design, the blades of 12v axial fans usually adopt airfoil design, which can reduce air resistance and improve the flow of air. The blades of the airfoil can generate greater thrust and higher static pressure when moving, thereby increasing the air volume and wind speed. In addition, the configuration of the number of 12V axial fan blades is also optimized, and the multi-blade design can provide more uniform airflow, but may increase wind resistance; While the low-blade design reduces the wind resistance, it may sacrifice some of the uniformity of the airflow. Therefore, designers need to find a balance between the two to ensure that the fan can provide good performance in different application scenarios.

In terms of material selection, manufacturers of 12v axial fans usually choose high-performance plastic or metal materials. Plastic is lightweight and low cost, easy to shape, suitable for mass production; Metal is more robust and suitable for more demanding environments. These materials not only need to have good mechanical strength and corrosion resistance, but also have great thermal properties to ensure that 12v axial fans can maintain stable performance during long-term operation.

In order to further improve the performance of 12v axial fans, manufacturers have also adopted some special design techniques. For example, some high-end axial-flow fans incorporate a hydrodynamic design that optimizes the shape of the blades and shells, reduces airflow separation and vortex generation, and thus increases fan efficiency and reduces noise. This design improvement allows the fan to provide higher air volume and static pressure while consuming less power.

Another key design element is the bearing system of the fan. In order to ensure the long-term stable operation of the fan, high-quality bearings are essential. These bearings reduce friction and improve the efficiency of the motor, while reducing wear and extending the service life of the fan.

The design and construction characteristics of 12v axial fans reflect their diversity and adaptability in modern electronic equipment cooling solutions. From the microscopic shape of the blades to the type of material chosen, every design detail is designed to optimize the performance of the fan, ensuring that the 12v axial fan delivers reliable and efficient heat dissipation in a variety of application environments. As technology continues to advance, future axial fan designs are bound to bring more innovations to meet increasingly stringent performance standards and environmental requirements.

English

English 中文简体

中文简体 عربى

عربى