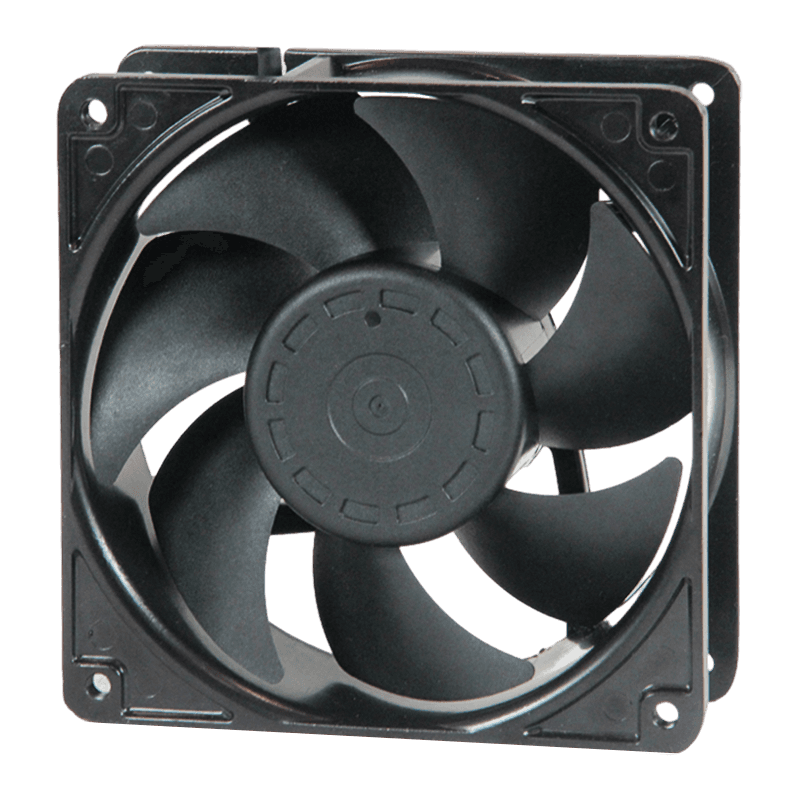

High quality wholesale axial flow fan for sale

Axial flow fan has become the key equipment of tunnel ventilation because of its high efficiency, low energy consumption and strong adaptability. The reversible axial flow fan, as a special designed axial flow fan, has brought revolutionary changes to the tunnel ventilation system. In this paper, the working principle of reversible axial flow fan in tunnel ventilation system will be discussed in depth, and how to adjust the airflow direction by changing the rotation direction to achieve more flexible and efficient ventilation effect.

Working principle and design characteristics

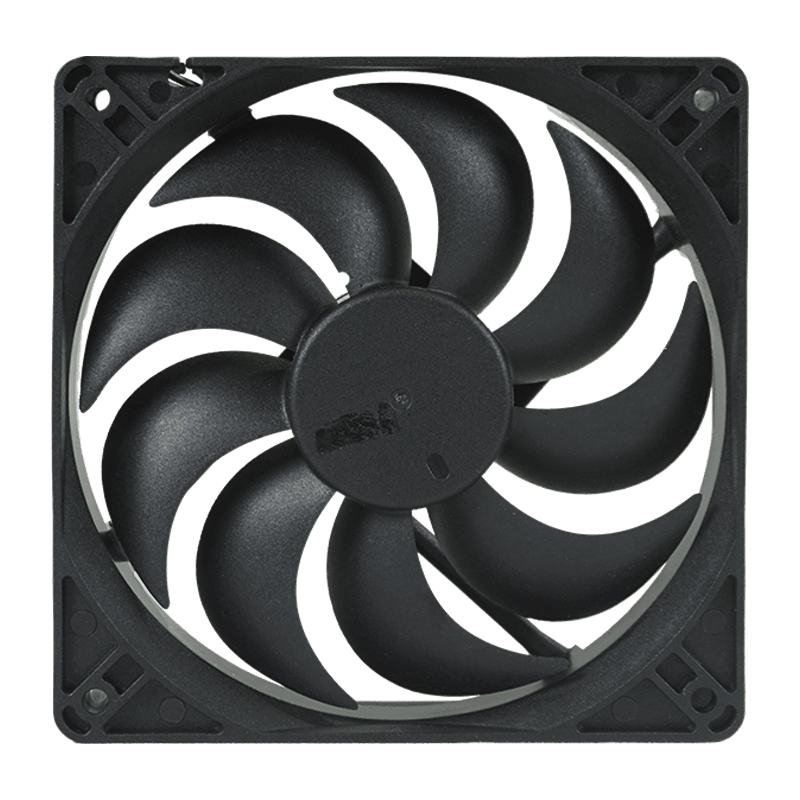

The core of the reversible axial flow fan is its unique design, which can change the direction of rotation according to the need to adjust the direction of the air flow. This capability is particularly important for tunnel ventilation systems, as the demand for airflow inside the tunnel changes with traffic flow, fire emergency situations and other factors. Under normal circumstances, axial flow fans operate in one direction to provide fresh air or exhaust gas; in emergency situations, such as when a fire occurs, by changing the rotation direction, the axial flow fan can quickly reverse the air flow, exhaust the smoke and harmful gases from the tunnel, and ensure the safe evacuation of personnel.

A mechanism for adjusting the direction of air flow

The change of rotation direction of the reversible axial flow fan is realized by the reversal of the motor. The circuit design inside the motor allows for rapid switching of the direction of current, thereby changing the direction of rotation of the motor. This process is usually done automatically by the control system, ensuring a quick response in case of an emergency. In addition, in order to ensure the stability and efficiency of the fan during inversion, the design of the blade is also crucial. The angle and shape of the blade need to be precisely calculated to ensure that good aerodynamic performance is maintained regardless of the forward or reverse rotation.

Hydrodynamic analysis

Hydrodynamic analysis is an indispensable part in designing reversible axial flow fan. With cfd (computational fluid dynamics) software, engineers can simulate the airflow distribution of a fan in different rotation directions and evaluate its efficiency and noise levels. This analysis helps to optimize blade design, reduce airflow separation and eddy currents, and improve the overall performance of the fan. For example, by adjusting the tilt angle and spacing of the blades, the airflow resistance can be effectively reduced, the air volume and static pressure can be increased, and the noise generation can be reduced.

Practical application case

In practical applications, the performance of reversible axial flow fans in tunnel ventilation systems is impressive. Taking a large highway tunnel as an example, the tunnel is equipped with a number of reversible axial flow fans, which not only provides stable ventilation in daily operations, but also successfully controls smoke diffusion in a sudden fire by rapidly reversing the direction of the air flow, which gains valuable time for rescue work. This case fully demonstrates the flexibility and efficiency of reversible axial flow fans in responding to emergency situations.

Conclusion

In summary, the application of reversible axial flow fans in tunnel ventilation systems not only reflects its innovation in design and fluid dynamics analysis, but also shows its great performance in dealing with complex conditions. By changing the direction of rotation to adjust the airflow direction, reversible axial flow fans bring great flexibility and safety to tunnel ventilation systems and become an indispensable key equipment in modern tunnel engineering. With the continuous progress of technology, we have reason to believe that the future axial flow fan will be more intelligent and efficient, and inject new vitality into the development of tunnel ventilation system.

English

English 中文简体

中文简体 عربى

عربى